(edit, had cylinder number mislabeled.)

I have always had what I would consider a repetitive ticking sound in my G8. It's never been anything like lifter tick from what I hear in the youtube videos but I have a sound nonetheless.

We recently did the VMS head and cam swap and noticed the #5 cylinder was black BLACK compared to all the rest. When I was stock, this was always the vicinity of where the sound appeared to be coming from when standing in front of the engine. I always thought it could be the fuel injector making the sound and considered the possibility of it being DOD lifter tick but I was never sure.

Post-head/cam install, the sound is back. That pretty much cancels out lifter noise since all new lifters have been installed but the sound is definitely coming from the same area. I'll try to explain when the sound is most prevalent: When I first start the car, everything sounds fine. There is typical valvetrain noise but it sounds good and healthy. Once I let the car warm up and start stepping on it 3-5k RPM, the ticking starts and it is very loud in the cabin of the car and underneath if I drop down and listen. It can be heard standing over the engine bay but a combination of all the other engine noises makes it a pain to focus on it.

Here is where it gets very difficult though, if I put it in PARK and step out with my stethoscope, I can't find where the sound is coming from. AND, if I take too long, it fades as the car idles. From my understanding, if it were lifter tick, it would be present at idle and be easily identifiable. So, I started thinking that maybe it was exhaust leak from the header. A trip to Jiffy Lube to get fuel injectors cleaned pretty much negated that theory since the smoke created from the process would have appeared in any leaks, and it did not come out anywhere other than my exhaust tips.

So now, I am out of ideas. I keep going back to that black #6 cylinder and trying to figure out why it was like that. New lifters, cam, pushrods, rocker arm trunnions, and spark plugs have been installed as of a few days ago so it has to be something that is still present in the system that was there before my recent install.

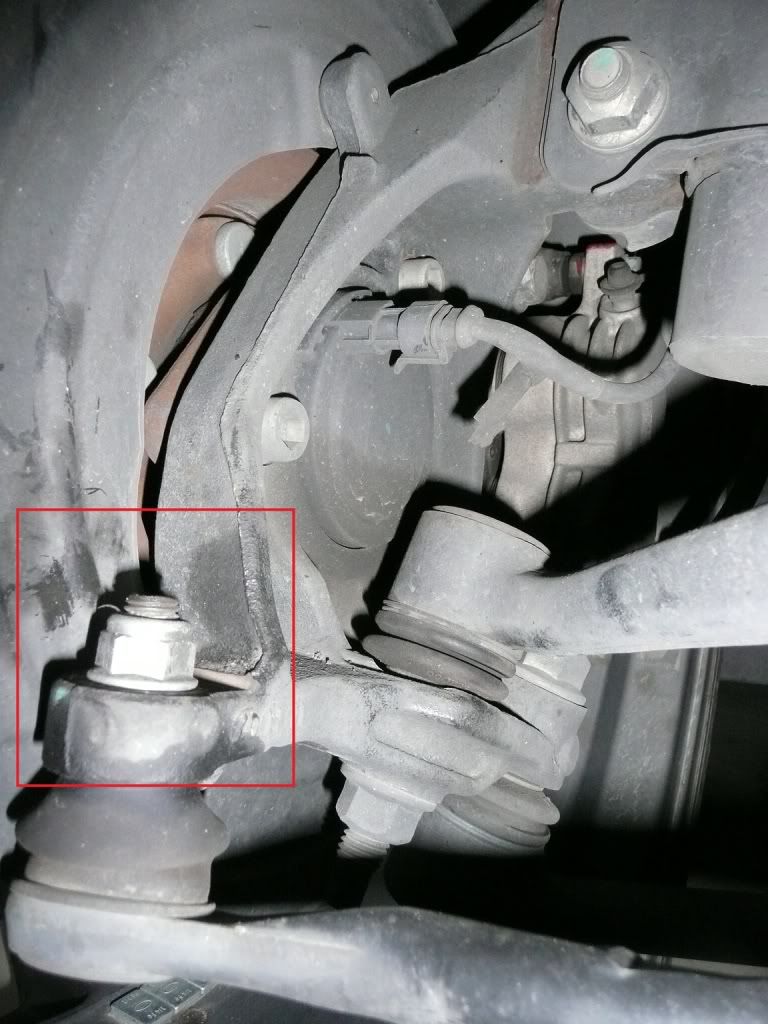

Looking for ANY help or ideas, I'm out there all evening with the car running, trying to figure it out. Perhaps this picture will help show that when I say black #6, I mean BLACK.

VIDEOS added:

Car warming up, sound is what is to be expected with the valvetrain. The tick is barely audible in this clip, as it always is, but it is not prevalent yet since I haven't revved the engine yet.

This is a 5 minute video but if you have the time, list to it to hear the transition of when the tick occurs from the beginning when I am simply revving the engine to when it begins afterwards:

This is the cammed exhaust note. It's sexy, but you can still hear that tick coming from the engine bay even from behind the car. This ticking sound is one of those sounds that almost appears to get louder the further you are away from it.

Reply With Quote

Reply With Quote