Campaign - ECM/TCM Update for OBD Improvements

# 08150: Service Update for Inventory and Customer Vehicles-OBD Improvements/Modified Electronic Calibration Info-Reprogram Engine and Transmission Modules

(Apr 23, 2008)

Subject:

08150 -- Service Update for Inventory and Customer Vehicles -- On-Board Diagnostic (OBD) System Improvements and Modified Electronic Calibration Information -- Reprogram Engine and Transmission Control Modules - Expires with 8 year/80,000 mile (130,000 km) Emission Controller Warranty Period

Models:

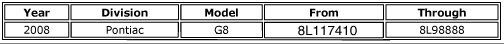

2008 Pontiac G8

Equipped with 6.0L V8 (RPO L76 - VIN Y) Engine and 6L80 (RPO MYC) Transmission

THIS SERVICE UPDATE INCLUDES VEHICLES IN DEALER INVENTORY AND CUSTOMER VEHICLES THAT RETURN TO THE DEALERSHIP FOR ANY REASON; AND WILL EXPIRE AT THE END OF THE INVOLVED VEHICLE'S 8 YEAR /80,000 MILE (130,000 KM) EMISSION CONTROLLER WARRANTY PERIOD.

Purpose

This bulletin provides a service procedure to reprogram the Engine Control Module (ECM) and Transmission Control Module (TCM) calibration on certain 2008 model year Pontiac G8 vehicles, equipped with a 6.0L V8 (RPO L76 - VIN Y) engine and 6L80 (RPO MYC) transmission. The revised calibrations include OBD system improvements and electronic calibration identification and calibration verification number changes that should be installed as soon as practical. To verify if an updated calibration is required, refer to the following procedure in this bulletin.

This service procedure should be completed as soon as possible on involved vehicles currently in dealer inventory and customer vehicles that return to the dealer for any type of service during the 8 year/ 80,000 mile (130,000 km) emission controller warranty coverage period.

Vehicles Involved

A list of involved vehicles currently in dealer inventory is available on the "Service Update Bulletin Information" link under the "Service" tab in DealerWorld (GM US), or attached to the Dealer Communication (Canada), used to release this bulletin. Customer vehicles that return for service, for any reason, and are still covered under the vehicle's 8 year / 80,000 mile (130,000 km) emission controller warranty coverage period, and are within the VIN breakpoints provided below, should be checked for vehicle eligibility in the appropriate system listed below.

IMPORTANT: Dealers are to confirm vehicle eligibility prior to beginning repairs by using the system below. Not all vehicles within the above breakpoints may be involved.

Calibration Information

Do not attempt to order the calibration number from GMSPO. The calibration numbers required for this service procedure are programmed into control modules via a Multiple Diagnostic Interface (MDI) or Tech 2® scan tool and TIS2WEB with the calibration update. Use TIS2WEB data version 4.5 for 2008 on or after 04/17/08 ; and on TIS DVD version 5.0 / 2008 or later, mailed to dealers beginning 05/07/08, to obtain the calibration. If you cannot access the calibration, call the Techline Customer Support Center and it will be provided.

Service Procedure

GMVIS must be checked to determine if a specific vehicle requires this action. If the system indicates that Service Update Bulletin 08150 remains 'open' and ECM/TCM reprogramming has not taken place, reprogram the ECM/TCM with the calibration update from TIS 2 Web.

Service Programming System (SPS)

For step-by-step programming instructions, please refer to SI and the Techline Information System (TIS) terminal.

Review the information below to ensure proper programming protocol.

IMPORTANT: ^ DO NOT program a control module unless you are directed by a service procedure or you are directed by a General Motors Corporation service bulletin. Programming a control module at any other time will not permanently correct a customer's concern.

^ It is essential that the Multiple Diagnostic Interface (MDI) or Tech 2® and the TIS terminal are equipped with the latest software before performing (SPS).

^ Due to the time requirements of programming a controller, it is recommended that an external power source be used to maintain system voltage. Stable battery voltage is critical during programming. To ensure trouble-free programming, GM recommends using one of the following external power sources:

- A Midtronics PCS charger

- A fully charged 12V jumper or booster pack disconnected from the AC voltage supply.

- Some modules will require additional programming/setup events performed before or after programming.

- Some vehicles may require the use of a CANDi module for programming.

- Review the appropriate service information for these procedures.

- DTCs may set during programming. Clear DTCs after programming is complete.

- Clearing powertrain DTCs will set the Inspection/Maintenance (I/M) system status indicators

Ensure the following conditions are met before programming a control module:

^ Vehicle System Voltage

- There is not a charging system concern. All charging system concerns must be repaired before programming a control module.

- Battery voltage is greater than 12 volts but less than 16 volts. The battery must be fully charged before programming the control module.

- Turn OFF or disable any system that may put a load on the vehicles battery, such as the following components:

- Twilight sentinel

- Interior lights

- Daytime running lights (DRL) - Applying the parking brake, on most vehicles, disables the DRL system

- Heating, ventilation, and air conditioning (HVAC) systems

- Engine cooling fans, radio, etc.

^ The ignition switch must be in the proper position. SPS prompts you to turn ON the ignition, with the engine OFF. DO NOT change the position of the ignition switch during the programming procedure, unless instructed to do so.

^ Make certain all tool connections are secure, including the following components and circuits:

- The RS-232 communication cable port.

- The connection at the data link connector (DLC).

- The voltage supply circuits.

^ DO NOT disturb the tool harnesses while programming. If an interruption occurs during the programming procedure, programming failure or control module damage may occur.

^ DO NOT turn OFF the ignition if the programming procedure is interrupted or unsuccessful. Ensure that all control module and DLC connections are secure and the TIS terminal operating software is up to date. Attempt to reprogram the control module. If the control module cannot be programmed, replace the control module.

1. Verify that there is a battery charge of 12 to 16 volts. The battery must be able to maintain a charge during programming. Only use approved Midtronics PCS charger, a fully charged 12V jumper, or booster pack disconnected from the AC voltage supply to maintain proper battery voltage during programming.

2. Reprogram the engine control module (ECM) and transmission control module (TCM). Refer to SI and Service Programming System (SPS) documentation for programming instructions, if required.

^ Connect the MDI or Tech 2® to the vehicle.

Important: Select J2534 MDI or Tech 2® Legacy Pass-Thru and Reprogram ECU from the Select Diagnostic Tool and Programming Process screen. The J2534 MDI will reprogram the module in less time than the Tech2® scan tool.

^ Select ECM Engine Control Module from the Supported Controllers screen.

^ Follow the on-screen instructions.

^ When ECM program is completed open driver door and turn off ignition for 30 seconds. Turn the ignition on and close the driver door.

Important: The TCM may have the same calibration numbers when programming Both the old and new TCM calibration numbers being the same is ok, General Motors.

^ Select TCM Transmission Control Module from the Supported Controllers screen.

^ Follow the on-screen instructions

3. Using the MDI or Tech 2®, clear all DTCs, if required

Information supplied courtesty of Alldatapro.com

Reply With Quote

Reply With Quote